PU Sandwich Panel Machine Description:

PU sandwich panel machine can be divided into PUR sandwich panel production line, PIR sandwich panel production line, PU rolling door production line, garage door panel production line.

The product of the production line–polyurethane composite board is a new wall building material with the best insulation, heat insulation, sound insulation, flame retardant, waterproof, light and environmental protection functions. It can be widely used in the outer wall of high-rise buildings and high-grade office buildings. Protection and decoration, industrial plants, cold storage, purification rooms and insulation containers.

For the continuous automatic production line of Quanlong polyurethane sandwich panels, the requirements for the workshop are about 120mx4mx8m.

Main Component of PU Sandwich Panel Machine:

Polyurethane composite board production line mainly consists of unwinding system, film cutting, forming machine system (with trimming device), steel plate preheating furnace, high pressure foaming system, double track, double track heating system, band saw cutting system, automatic palletizer And other equipment.

Hydraulic Discharge System of the PU Sandwich Panel Machine:

The production line consists of two upper and lower unwinders, each of which consists of an unwinding frame, a loading trolley and a hydraulic station. The uncoiler adopts a hydraulic cantilever tensioning type, which is mainly used for steel coil feeding and recycling.

Hydraulic Discharge System

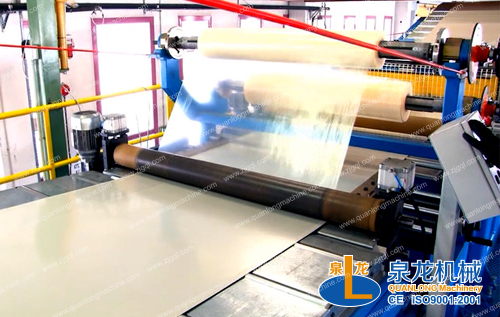

PU Sandwich Panel Machine Film Cutting Device:

The film coating device sticks the film on the flat plate to avoid damage to the paint surface of the plate.

During operation, under the action of the fast driving roller, a certain amount of sheet material is stored in front of the molding machine. When the stock sheet is traveling in the molding machine, the sheet at the cutting device is stationary with respect to the broach, and the broach is decelerated by the motor. Driven by the machine, the plate is quickly pulled off.

The film laminating device and the cutting device are integrated, and the film is cut off together with the sheet.

Film Cutting Device

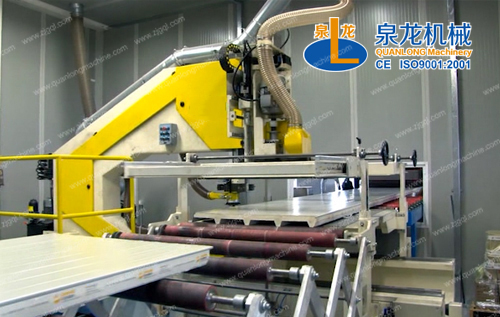

PU Sandwich Panel Machine Archer Molding Machine:

The PUR polyurethane sandwich panel production line forming machine system mainly consists of an upper forming machine, a lower forming machine, a press machine platform, and upper and lower interface raceways. It can also be designed according to the needs of customers.

Archer Molding Machine

Heating System of PU Sandwich Panel Machine:

The heating method of the preheating furnace is hot air heating, and the heating source is provided by the customer himself, which may be steam, gas, fuel…

Heating System

High Pressure Foaming System of PU Sandwich Panel Machine:

The high-pressure foaming system used in the production line has accurate measurement and high stability, and the floating environment on the site is small, which can ensure the health of the staff.

The function of the foaming system is mainly to provide a cycle for various raw material components (isocyanate, polyol blowing agent, catalyst, flame retardant), to detect the temperature and flow rate of each component, and to compensate the temperature and flow rate as required. Finally, the components are mixed in the required ratio and uniformly sprayed between the upper and lower formed steel sheets.

High Pressure Foaming System

Double Track System of the PU Sandwich Panel Machine:

The double track is mainly composed of upper and lower steel tracks, left and right side belts, formwork and transmission mechanism.

The function of the upper and lower tracks is mainly to overcome the foaming pressure generated by the polyurethane foam to solidify and shape, and determine the thickness of the composite board and the speed of the production line; the function of the side belt is mainly to overcome the lateral tension generated by the foaming of the polyurethane, and determine the composite sheet. Width, and precise guiding of the composite board during the production process; double track as a continuous running movable mold, to avoid sheet deformity and surface scratches, to ensure high quality composite sheet.

Double Track System

PU Sandwich Panel Machine Band Saw Cutting System:

The band saw machine is composed of a front roller table, a gauge encoder device, a saw blade guiding rotary member, a band saw member, a table, a telescopic roller table, a rear roller table and the like.

The main function of the band saw machine is to automatically measure through the length gauge encoder according to the required plate length parameters, and automatically cut the continuous finished board without stopping the production line; at the same time, absorb the dust generated during cutting.

Band Saw Cutting System

Cold Bed of PU Sandwich Panel Machine:

The finished sandwich panel is sent to the cold bed by the roller conveyor for cooling. After cooling, the roller enters the automatic palletizer.

Cold Bed

PU Sandwich Panel Machine Automatic Palletizer:

The palletizing equipment sends the finished finished sheet to the designated position, and the robot arm automatically completes the stacking of the sandwich panel from the single sheet.

Automatic Palletizer

PU Sandwich Panel Machine Electrical Control System:

Control the entire line with PLC and inverter.

Electrical Control System

Packing System of PU Sandwich Panel Machine:

The plastic sheet wrapped with the palletizing machine is covered with a plastic film to prevent damage to the outer surface of the finished sheet for storage and transportation.

Packing System

| Length | Less than or equal to 3m(Minor differences based on production speed) |

| Width | 900-1020 mm |

| Thickness | 30-200 mm(Steel corrugation is not included) |

| Coil Thickness | 0.37-0.8 mm |

| Coil Maximum Width | 1250 mm |

| Coil Weight | 10T |

| Steel Coil Inner Diameter | Φ508、Φ610 mm |

| Maximum Production Speed | 6m/min |

| Production Line Length | About 115 Meters |

| Production Line Working Height | 1200mm(PU board height from the ground) |

| Foam Placement Pressure | 150-200 bar |

| Control System | Imported brand PLC control |

| Total Power | About 300kw |

| Voltage | 380V/3/50 Hz |

| Control Voltage | 24V;110V;220 V |

| Gas Supply Pressure | 0.7 Mpa |