CZ interchange forming machine is the result of the latest research and development of our company. Features of the device: fast and freely change product specifications, saving change time and easy operation. The universal shear combination device can be cut for each type of C-shaped steel and Z-shaped steel, saving time and saving cost.

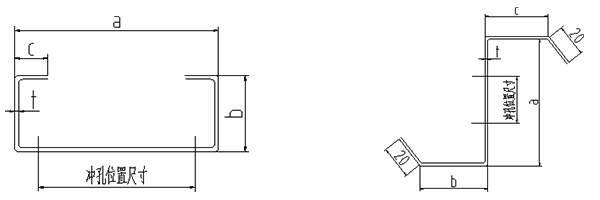

Plate Pattern of CZ Interchange Forming Machine:

CZ interchange forming machine production specifications

1. Any change between C-shaped steel (a=80-300,) and any change between waist height (b=35-80).

2. Any transformation between Z-shaped steel (a=120-300,) and any change between waist height (b=35-80).

3, sheet thickness: thickness 1.5 mm ~ 3.0 mm

4, can be pressed sheet: Q235, Q345 galvanized steel

5, production speed: 20-28m / min

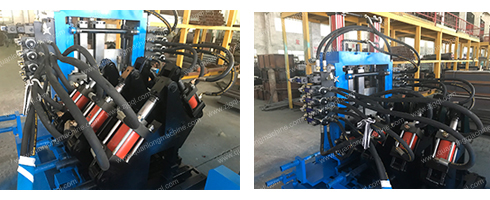

The main components of the CZ interchange forming machine

CZ interchange molding machine mainly consists of passive inner support type discharge rack, feeding guide mechanism, pinch roller mechanism, sheet leveling mechanism, pinch roller, punching and cutting mechanism, forming main machine and hydraulic station system. , PLC computer control system, finished product rack, etc.

CZ fast switching specifications

From C-shaped steel to Z-shaped steel or from Z-shaped steel to C-shaped steel, the model can be changed by rotating 180 degrees.

Due to the use of the overall archway movement, the electric gearbox is adjusted, the linear guide maintains the accuracy, and it takes only 3-5 minutes to change the specification. The traditional method of changing the looper and changing the specification takes 20-40 minutes each time. Many manufacturers are around 2 hours.

Button Change:

Button change type: electric adjustment size, easy to operate

Hand-cranked quick change: More precise adjustment of dimensional deviation.

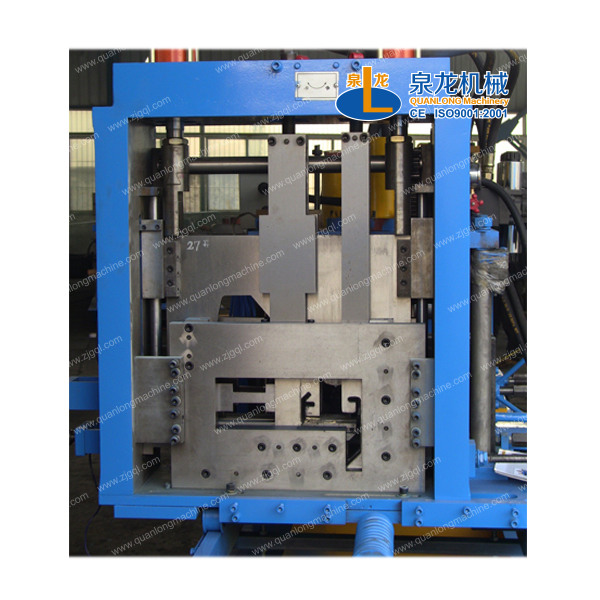

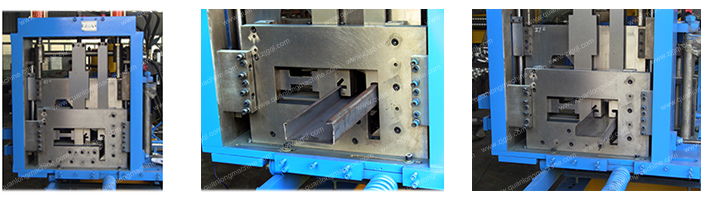

Universal Shearing Device of Forming Machine:

The cutting device has successfully developed a stepless adjustment tool, which has changed the trouble of requiring a pair of molds for each specification. It saves time and is also suitable for producing various specifications of unconventional sizes. Since each type of specification needs to be equipped with a pair of molds, stepless adjustment of the tool not only saves the cost of the mold, especially during the debugging process, when the height of the two sides is inconsistent and exceeds the molding die, the multi-function cutting blade can be adjusted, while the original conventional mold is Failure to pass will result in waste and new adjustment after segmentation cutting, resulting in waste of raw materials in the production process

Oblique Punching Device:

Advanced punching device for faster punching and higher punching accuracy, further increasing production speed.

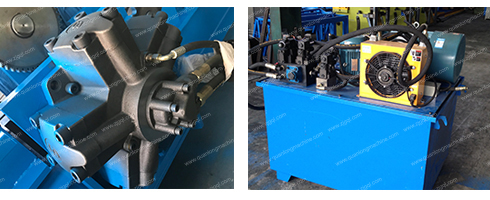

Hydraulic System of Forming Machine:

Increase the hydraulic system, the motor power of the configuration is 30KW. In order to improve the working efficiency, the domestic famous brand of five-star hydraulic motor is selected.