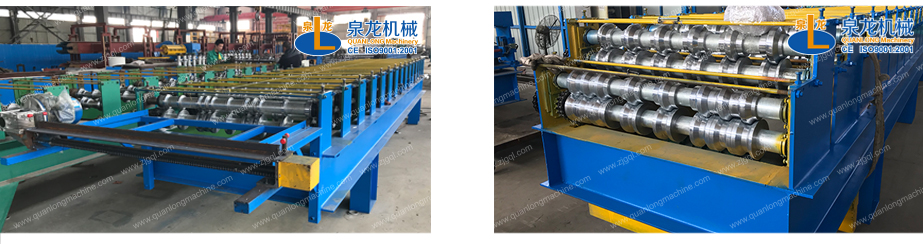

The multi-functional sandwich panel production line is a special production equipment for new building materials. The main function of the multi-functional sandwich panel production line is to composite color steel on thicker and lighter inner core material EPS board or rock wool board, and run continuously. The precise cutting of the composite panel under the conditions realizes mechanization and automation of the entire production process.

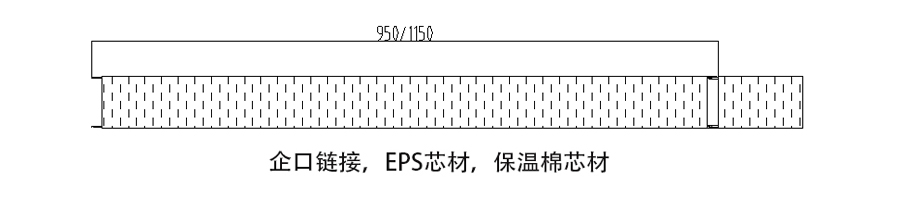

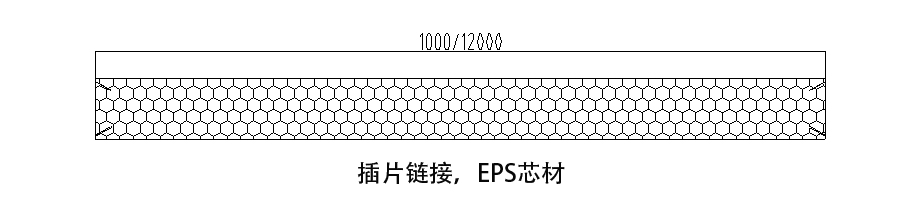

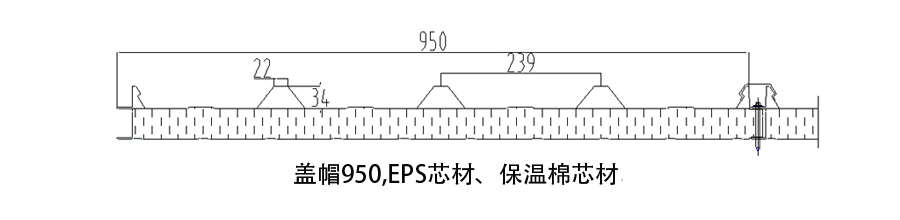

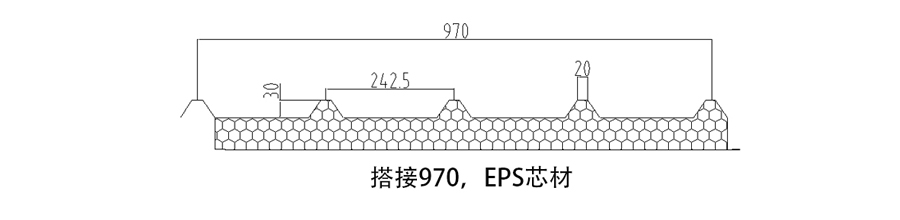

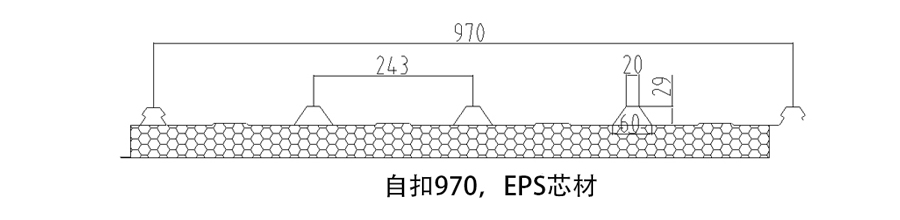

The multi-functional sandwich panel production line developed by the company uses color-coated steel sheets as the surface material, self-extinguishing polystyrene, polyurethane, glass wool and rock wool as core materials, and is heated in a continuous molding machine with thermosetting glue. Ultra-light building panels made of pressure composite. The multi-functional sandwich panel production line can produce EPS flat panels, EPS tongue-and-groove plates, EPS corrugated plates, rock wool flat plates, rock wool tongue and groove plates, rock wool corrugated plates and other plate types. The core materials that can be used in the multi-functional sandwich panel production line are: foam, expandable polystyrene foam, rock wool, polyurethane and suitable core material.

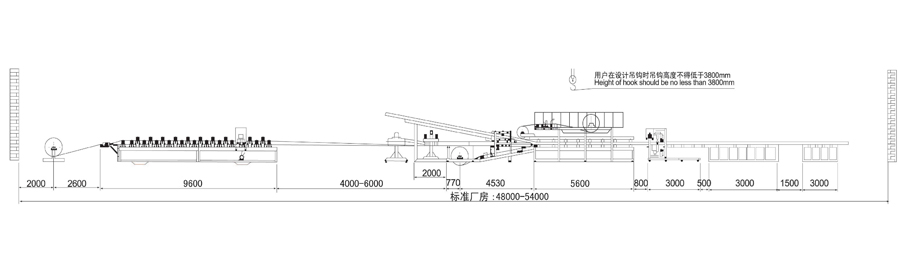

Layout:

Details:

1. Single-layer corrugated and double-layer corrugating machine, which can be designed according to customer needs.

2. The composite host has 24 rolls, 29 rolls, 50 rolls, different versions of different configurations, fully meet your needs.

3. Single flying saw, double flying saw two cutting methods, different configurations for different core materials, and fully enclosed rear cutting device, safer and more sanitary.

4. Slitting machine, capping machine, edge banding machine, rock wool sandwich board essential configuration.

| Plant Height | Greater than 5,500mm |

| Length | Foam is greater than 40,000mm and rock wool is greater than 60,000mm |

| Power Supply | Three-phase five-wire system |

| Foundation | Should be concrete flat ground |

| Total Capacity | 35KW |

| Hoisting Machinery | Lifting a single beam with a weight of 5 tons, the effective stroke is 28M. Hook off the ground > 4,000mm |

| Coil Thickness | 0.4-1.0 |

| Coiler Width | 1250mm |

| Coil Weight | 5T |

| Steel Coil Inner Diameter | Φ500mm Φ600 mm |

| EPS production line plant requirements | 30mx8mx3.5m |

| Rock wool production line plant requirements | 60mx8mx3.5m |

| EPS Production Line | 50-250mm |

| Rock Wool Production Line | 50-150mm |